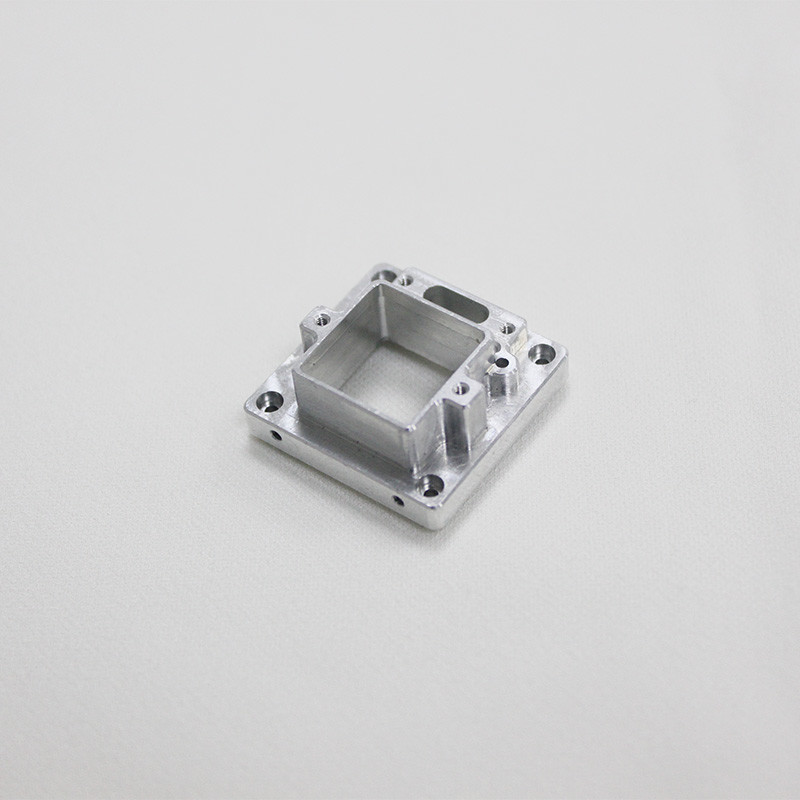

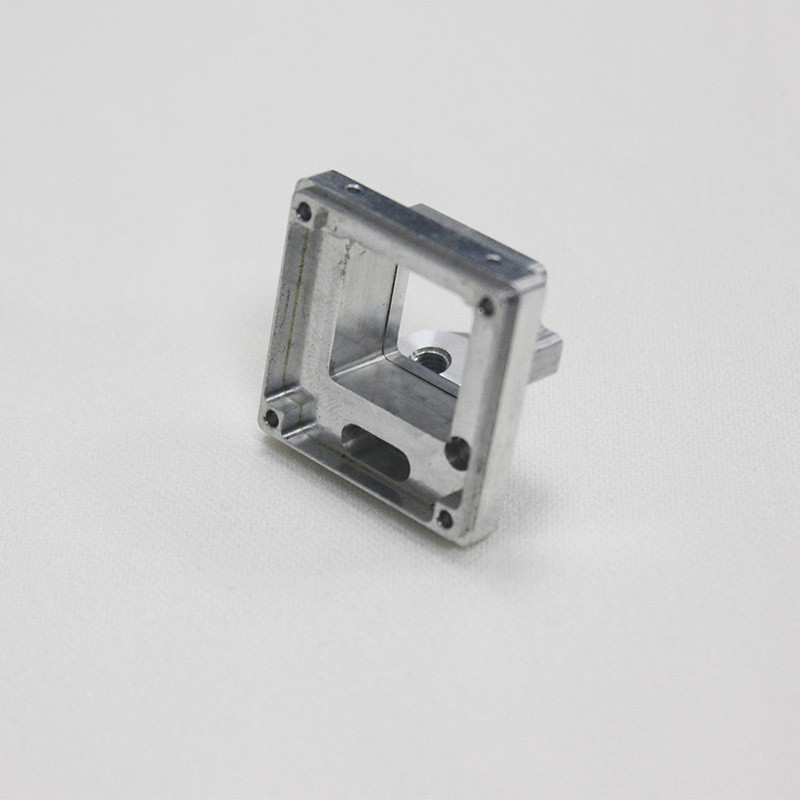

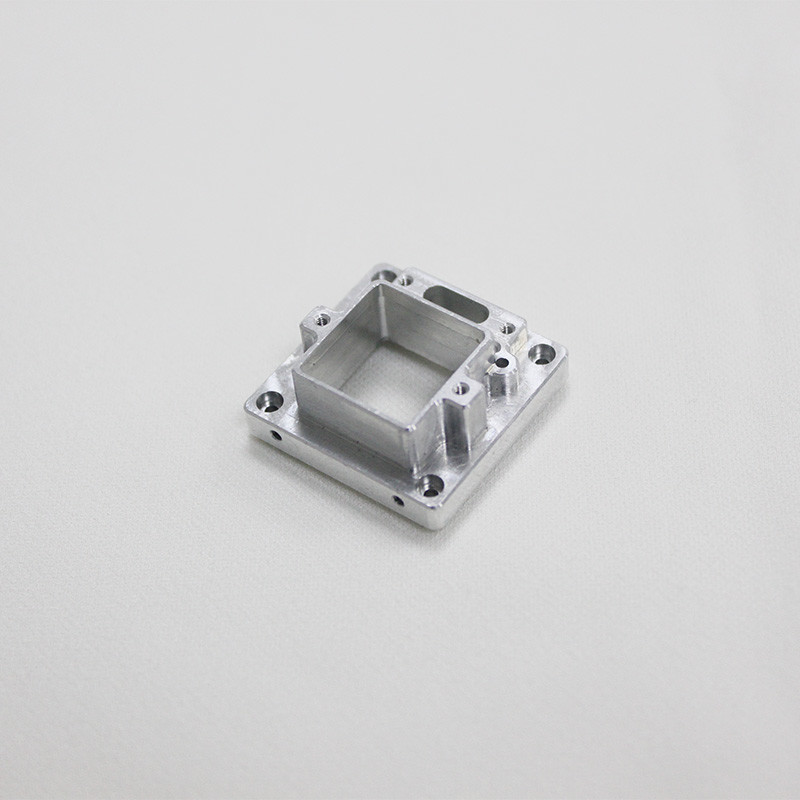

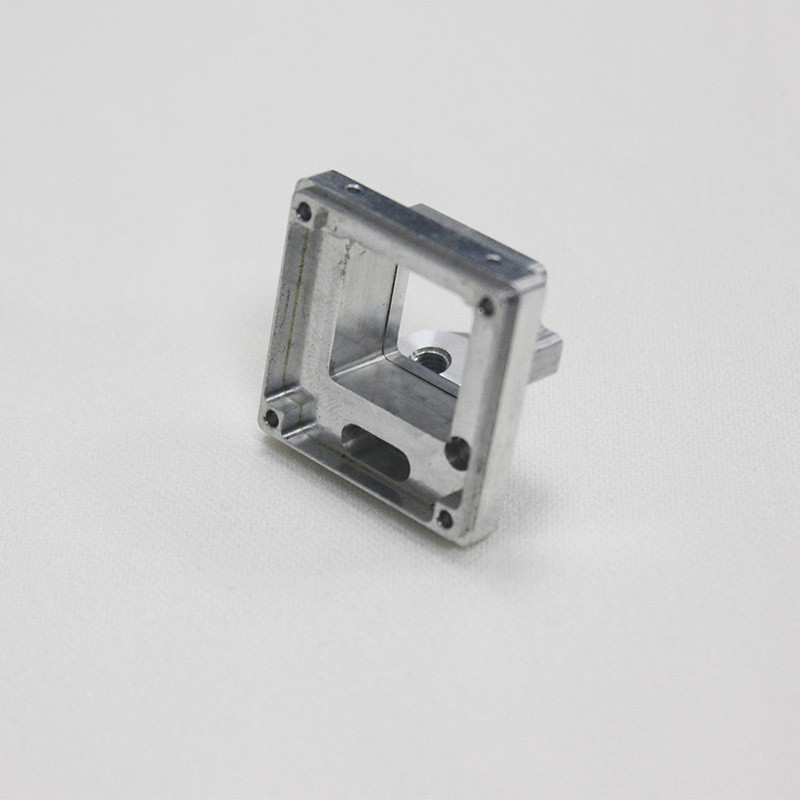

Precision Aluminum CNC Parts For Camera Panel Anti Oxidation

Rustproof

Quick detail of CNC Machining Parts

CNC Machining Type: Broaching, DRILLING, Etching / Chemical

Machining, Laser Machining, Milling, Other Machining Services,

Rapid Prototyping, Turning, Wire EDM

Material Capabilities: Aluminum, Brass, Bronze, Copper, Hardened

Metals, Precious Metals, Stainless Steel, Steel Alloys

Micro Machining or Not: Micro Machining

Model Number:

Shaping model: Stainless steel CNC turning parts

Material: Aluminium,stainless still

Method: CNC turning parts

Surface treatment: Polishing,sandblast,anodizing

Tolerance: + - 0.001 mm

Weight: 0.2~3 kg’

Surface Treatment: Powder coating, Zinc plating, chrome plating

Color: custom made

Size: custom made

Our Service: OEM&ODM CNC machining,as per customer's

requirement

Equipment: CNC Machining Center,CNC lathe,CNC turning,milling

Product Categories: Monitor accessories

Type: Adult finger clip/Silicone/Neonate Wrap

Cable Material: Medical TPU

Cable Color: Gray Cable Length: 3M

Usage: Pressure Sensor, Direct spo2 sensor connected to the

monitor, no need for extension cable.

Equipment: 3/4/5axis Machine, CNC lathe,CNC turning, CNC milling

Certificates:ISO 9001:2015 & IATF 16949

Note

What are the benefits of CNC precision parts processing?

Parallel machine tools: The functions of commonly used machining

centers are relatively fixed. Vertical machining centers,

horizontal machining centers, or machining centers, turning

centers, etc. are combined to form a machining system, which

increases the machining range and processing capacity of the

machine tool.

Automatic protection of machine tool overload: The machine tool can

automatically protect the machine tool according to the load during

processing. When the load exceeds the maximum load set by the

machine tool, the machine tool will automatically shut down. The

load size can be set and changed by yourself.

Machining dynamic entity simulation: During the machining process,

the machining state of certain parts of the machine tool is not

easy to observe. If the dynamic entity simulation function is

added, the machining state of the workpiece can be observed at any

time, which can prevent undesirable phenomena in machining, such as

Knife, over-cutting, not only, unreasonable steps, etc.

On-line inspection of workpieces: also called real-time inspection,

which means real-time inspection of workpieces in the process of

processing to find and correct errors in time. This function can

effectively avoid the problem of re-clamping and positioning caused

by unqualified inspection after conventional processing, shortening

production time and improving production efficiency.

Adaptive control: The machine tool with this function can detect

the changes in the cutting conditions (such as cutting force,

temperature, etc.) that it senses during the machining process, and

control the machine tool to change the cutting amount in time

through the adaptive control system, so that the machine tool and

the tool are always Maintain the best condition, so as to obtain

higher cutting efficiency and processing quality, and extend the

service life of the tool.

aluminum profile handle is widely used in all kinds of home

decoration.For example used in wardrobes,cabinets,window and

door.Custom aluminum extrusions provide personalized features and

durability for a wide range of products,further surpassing customer

requirements. We have professional aluminum profile deep processing

equiment. Such as CNC machines, powder coated, anodized,

electrophoresis, polishing, punching,ect. Shenghai Aluminium

Extrusion Profiles is one of the leading manufacturers.Can provide

professional production CNC machining anodized aluminum door

handles solutions.We provide you with Quality, Time and Price.

We can make any aluminum parts by CNC machining. We meet any

aluminum machining required by customers.

We can offer CNC machining partd for custom design.

Product Name

Pump Impeller / Aluminum anodized parts

Material

Aluminum / Steel

Standard

Customized Fabrication (Custom provide designs)

Application

Pumps / Bicycle

Description of CNC Machining Parts

CNC Turning

Turning is a machining process which employs single-point cutting

tools to remove material from the rotating workpiece.In CNC

turning, the CNC machine-typically a lathe or turning machine-feeds

the cutting tool in a linear motion along the surface of the

rotating workpiece, removing material around the circumference

until the desired diameter is achieved, to produce cylindrical

parts with external and internal features, such as slots, tapers,

and threads.Operational capabilities of the turning process include

boring, facing, grooving, and thread cutting.

Product Description:

Stainless steel material is featured with high strength,high

hardness and corrosion resistance. After heat treatment,products

have better mechanical property and reach great pressure

resistance. It's widely used in fields such as construction,sea

devices, aviation,military equipment,ect.Quality is our culture

,the company equipped with numerous advanced machine such as CNC

machining center,high speed drilling and milling machining center

etc.,and inspection equipment including callipers,two dimensional

measring instrument,height ect.

Application of CNC Machining Parts

--OEM CNC Machining

-- Mining Accessories

-- Machinery Accessories

-- Truck Parts

-- Auto Parts

-- Industrial Parts

Automotive, Automation, Test systems, Sensors, Medical, Sports,

Consumer, Home appliance,Electronic, Pumps, Computers, Power and

energy, Architecture, Printing, Food, Textile machinery, Optical,

Lighting, Security and safety, AOI, SMT equipment, etc.

Main Materials of CNC Machining Parts

1. Aluminum:Al6061, Al6063, Al6082, Al7075, Al2024, Al5052, A380,

etc.

Stainless Steel:SS201,SS301,SS303, SS304, SS316, SS416, etc.

Steel:Mild Steel, Carbon Steel, 4140, 4340, Q235, Q345B, 20#, 45#,

etc.

Brass:C35600, C36000, C37700, C37000, C37100, C28000, C26000,

C24000, C22000, etc.

Copper:C11000, C12000, C12200, C10100, etc.

Iron:20#, 45#, Q235, Q345, Q3458, 1214, 12L14, 1215, etc.

Plastic:POM, Peek, PMMA, ABS, Delrin, Nylon, PVC, PP, PC, etc

Surface Treatment of CNC Machining Parts

1. Stainless Steel:Brushed and Polishing, Passivating,

Sandblasting, Laser engraving, Gold Plating Etc.

2. Steel:Zinc plating, Oxide black, Nickel plating, Chrome plating,

Carburized, Powder Coated

3. Aluminum Parts:Clear Anodized, Color Anodized, Sandblast

Anodized, Chemical Film,Brushing,Polishing,Power Coated, Nickel

Plated Etc.

4. Plastic:Plating gold (ABS), Painting, Brushing (Acylic), aser

engraving

Why choose us? / our advantages / our serves:

1. 20 years experience;

2. TS16949 & ISO9001 certificated;

3. Over 5 years' vendor of loss Automotive, SMP Automotive;

4. Small quantity accepted;

5. High quality and reasonable price;

6. Delivery on time.

One-stop Solution

From mold design, mold making, machining, fabrication, welding,

surface treatment, assembly, packing to shipping

Quality Guarantee

We have a professional team to control the quality. Experienced

engineers, precision machines, CMM and QC system

Customer Service

Every client is served by a specialized sales for timely technical

support and after-sales service

1. High Precision, New Technology, Competitive Price for Casting

and machining

2. Advanced casting machines available.

3. All kinds of facility, CNC machining, turning, milling, tapping,

drilling, polishing, punching, etc...

4. Competitive Prices, Excellent Service, and Good Lead Time.

Quality control

1. Quality control :The defective products rate is 0.1%. Imported

material 100%.

2. Reasonable price , Precision made.Experience & Reasonable QC

that you can reply on.

3. Each part would be given 100% test and tryout before shipment.

4. Adequate supply capacity. Punctual delivery time.

(1) Material inspection--Check the material surface and roughly

dimension.

Production first inspection--To ensure the critical dimension in

mass production.

Sampling inspection--Check the quality before sending to the

warehouse.

Pre-shipment inspection--100% inspected by QC assistants before

shipment.

FAQ

Q: What kinds of information do you need for quote?

A: Kindly please provide the CNC Machining Parts drawings in PDF,

if provide in STEP or IGS will be better.

Q: What shall we do if we don't have CNC Parts drawings?

A: Please send your sample to our factory, then we can copy and

provide you better solutions. If send us pictures or drafts with

dimensions(Length, Hight, Width), CAD or 3D file will be made for

you.’

Q: What’s your machining scope?

A: CNC turning parts machining

CNC milling parts machining

CNC turning and milling machining

Q: What type of material we can process?

A: Stainless Steel :SS201,SS301, SS303, SS304, SS316, etc

Steel: 4140, 4340, Q235, Q345B, 20#, 45# etc

Brass :HPb63, HPb62, , HPb59, H59, H68, H80etc

Copper : C11000,C12000,C12000 C36000 etc

Aluminum : AL2024,AL6061, Al6063, AL7075, AL5052, etc

Titanium : TA1,TA2,TB1,TC4,TC18, TI GRADE2,GRADE5

What are the benefits of CNC precision parts processing?

1. Multi-axis control and multi-axis linkage: The commonly used

machining centers are mostly three-axis linkage. By increasing the

swing angle and increasing the rotation coordinates, it can form

four-axis linkage, five-axis linkage, seven-axis linkage, and even

more-axis linkage processing. center.

2. Parallel machine tools: The functions of commonly used machining

centers are relatively fixed. Vertical machining centers,

horizontal machining centers, or machining centers, turning

centers, etc. are combined to form a machining system, which

increases the machining range and processing capacity of the

machine tool.

3. Tool breakage alarm: use infrared, acoustic emission, laser and

other detection methods to detect the tool. If tools are found to

be worn or damaged, promptly alarm, automatically compensate or

replace spare tools to ensure product quality.

4. Tool life management: unified management of multiple blades on a

tool, or several tools working at the same time, to improve

processing efficiency.